As the world continues its transition towards renewable energy sources, solar power has emerged as a leading contender in the quest for sustainable electricity generation. Solar panels, also known as photovoltaic (PV) panels, are the key components of solar energy systems that capture sunlight and convert it into electricity.

Over the years, significant advancements have been made in solar panel technology, including the integration of rare earth metals. Let us explore the evolution of solar panels, their composition before the inclusion of rare earth metals, and the remarkable improvements they have helped bring about.

The concept of harnessing sunlight to generate electricity dates back to the mid-19th century, but it was not until the 1950s that practical solar cells were developed.

Early solar panels were primarily made of silicon, a semiconductor material with the ability to convert sunlight into electricity through the photovoltaic effect. However, the efficiency of these early panels was limited, reaching only around 6% to 8%, which hindered their widespread adoption for commercial use.

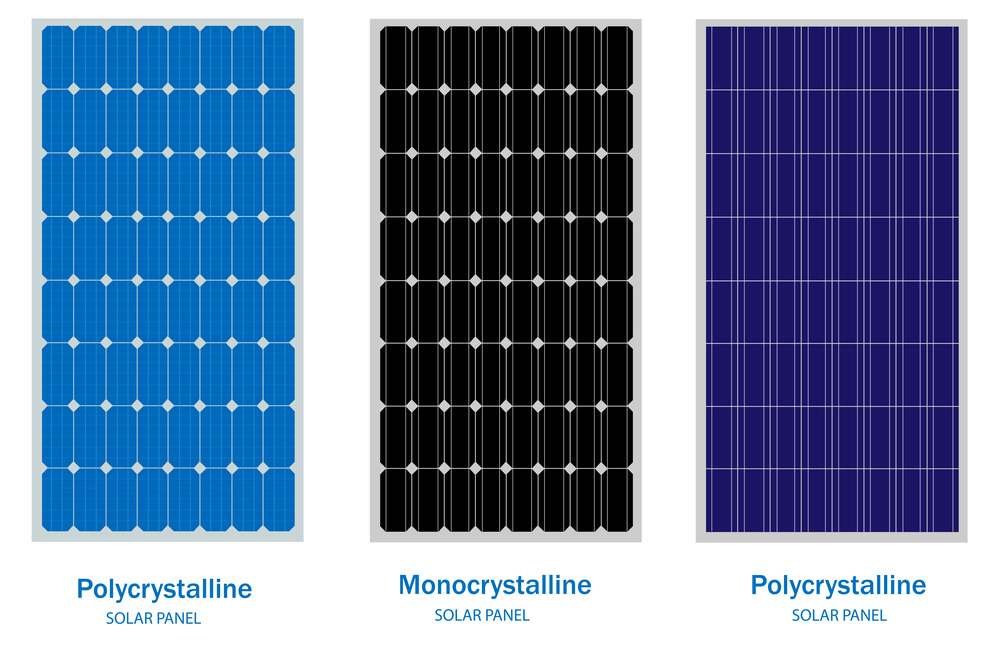

Traditional solar panels, also known as first-generation solar cells, predominantly consist of crystalline silicon, commonly found in two main forms: monocrystalline and polycrystalline silicon. These panels have been the bedrock of solar energy production for several decades, exhibiting reasonable efficiency levels and a proven track record of reliability.

Monocrystalline silicon solar panels are made from a single crystal structure, resulting in a highly uniform and efficient material. These panels typically boast efficiency levels in the range of 15% to 20%, with some high-end models reaching up to 25%. While monocrystalline panels have proven effective, their production costs are relatively high due to the complex manufacturing process required to create single-crystal structures.

Polycrystalline silicon solar panels, on the other hand, are manufactured using multiple silicon crystals, which are cheaper to produce but slightly less efficient. Their efficiency usually ranges from 13% to 16%, making them a more budget-friendly option for residential and commercial installations.

In recent years, researchers and engineers in the renewable energy sector have been exploring new materials and technologies to improve solar panel efficiency and reduce costs. One significant breakthrough has been the integration of rare earth metals (This article explains exactly what REE metals are) into solar cells, unlocking unparalleled improvements in performance.

Rare earth metals are a group of 17 elements found in the periodic table. Despite their name, some of these elements are not particularly rare, but they are challenging to mine and extract in economically viable quantities. The most commonly used rare earth metals in solar panels are ;

- neodymium

- dysprosium, and

- praseodymium

1. Enhanced Light Absorption

Rare earth metals are doped into the silicon material of solar cells to enhance their light absorption capabilities. This doping process helps the cells capture a broader spectrum of sunlight, including wavelengths that traditional silicon cells struggle to absorb efficiently.

2. Improved Charge Transport

The presence of rare earth metals enhances the movement of electric charge within the solar cell, leading to more effective electron-hole separation. This process reduces energy loss and increases the overall efficiency of the solar panel.

3. Resistance to Temperature Extremes

Solar panels with rare earth metals exhibit improved stability and performance in extreme temperature conditions. This makes them more suitable for installations in regions with varying climate patterns.

4. Thinner Solar Cells

Rare earth metals allow for the production of thinner solar cells with enhanced light-trapping capabilities. Thinner cells not only reduce material costs but also pave the way for flexible and lightweight solar panels that can be integrated into various applications.

The inclusion of rare earth metals in solar panels has marked a significant leap in efficiency compared to traditional silicon-based panels. Depending on the specific combination of rare earth elements and the manufacturing process, the efficiency gains can be substantial.

Third-generation solar cells, which utilise rare earth metals, have demonstrated efficiencies surpassing 30%.

These advanced solar cells, often known as multi-junction or tandem solar cells, consist of multiple layers of semiconductors, each designed to capture different wavelengths of sunlight. By stacking these layers and combining rare earth metals, researchers have achieved stunning efficiency levels, far beyond the capabilities of first-generation solar cells.

The integration of rare earth metals into solar panels has proven to be a game-changer, significantly enhancing efficiency and performance.

By utilising REE-enhanced solar panels, we can harness the sun’s energy more effectively and move closer to a sustainable, clean energy future.

As research and development in the field of solar technology continue to progress, we can expect further improvements in efficiency and cost-effectiveness, ultimately making solar power an increasingly prominent player in our pursuit of a greener planet.

The majority of global rare earth production is concentrated in a few countries, making supply chains vulnerable to geopolitical uncertainties. Additionally, the extraction and processing of rare earth elements can have environmental and social impacts if not managed responsibly. Please read documents on our Corporate Governance Page for more information about our approach.

Rare Earth Elements (REEs) comprise of 17 chemical elements that belong to the lanthanide series of the periodic table. Lanthanide elements are silvery-white metals that are generally soft, malleable, and ductile. They have high melting points and are highly reactive, particularly when finely divided.

| Lanthanum (La) | Cerium (Ce) | Praseodymium (Pr) | Neodymium (Nd) | Promethium (Pm) | Samarium (Sm) |

| Europium (Eu) | Gadolinium (Gd) | Terbium (Tb) | Dysprosium (Dy) | Holmium (Ho) | Erbium (Er) |

| Thulium (Tm) | Ytterbium (Yb) | Lutetium (Lu) | Scandium (Sc) | Yttrium (Y) |

Some of the elements, such as gadolinium and erbium, exhibit notable magnetic properties. The lanthanides also possess similar crystal structures and form various colored compounds, which are often used in the production of pigments and dyes.